The plastic industry is one of the typical high-emission and high-pollution industries, and it is also a potential field for China to achieve the synergistic effect of pollution reduction and carbon reduction. As an important material in people's production and life, plastic has high efficiency and wide application range. At present, no other materials can fully replace it. Biodegradable plastics have significant environmental benefits, but they are still in the initial stage of development, and the production cost is high, so it will take some time to achieve full market popularization. In this context, expanding the scale of plastic recycling is a more economical and feasible path in the short term.

Recycled plastics refer to the plastic raw materials obtained from waste plastics after processing by pre-treatment, melting granulation, modification and other physical or chemical methods, which have the characteristics of pollution reduction, carbon reduction, recycling advantage and so on. Therefore, it is of great significance for the plastic industry to achieve the goal of carbon neutrality to strengthen the policy guidance for the application of recycled plastics, improve the recycling rate of waste plastics and expand the proportion of recycled plastics.

A、Expanding the use of recycled plastics is crucial to promote the collaborative promotion of pollution and carbon reduction

One is to reduce plastic pollution.In 2020, China produced more than 60 million tons of plastic waste, about 70 percent of which was buried or incinerated, polluting groundwater and soil and releasing toxic gases to harm health. Expanding the proportion of recycled plastics will effectively improve the recycling rate of waste plastics and reduce pollution from the source.

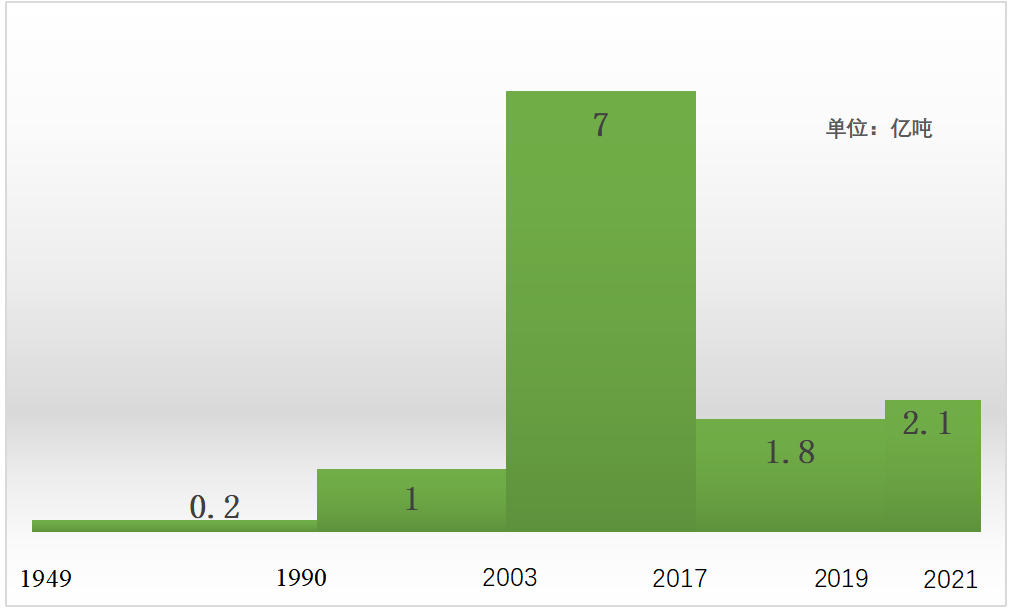

Second, it can reduce dependence on oil resources.It is estimated that in 2021, China's plastics industry will consume 200-400 million tons of oil. Each ton of recycled waste plastic can replace about 0.67 tons of resin raw materials, and can save about 1 ton of oil resources. At present, China has about 1 billion tons of waste plastic, and increasing the use of recycled plastics will help reduce China's dependence on foreign oil resources.

Third, it can reduce carbon emissions. In 2021, China will produce 110 million tons of primary plastic. If the production of 1 kilogram of plastic releases 2.3 kilograms of carbon dioxide (excluding carbon emissions from upstream raw materials), the plastic industry will release at least 254 million tons of carbon dioxide, accounting for about 2% of China's total carbon emissions. Producing 1 kilogram of recycled plastic emits only 1.4 kilograms of carbon compared to the original plastic, which reduces carbon dioxide emissions by 0.9 kilograms, or 39 percent.

B、The application of recycled plastics in China has a good foundation for development

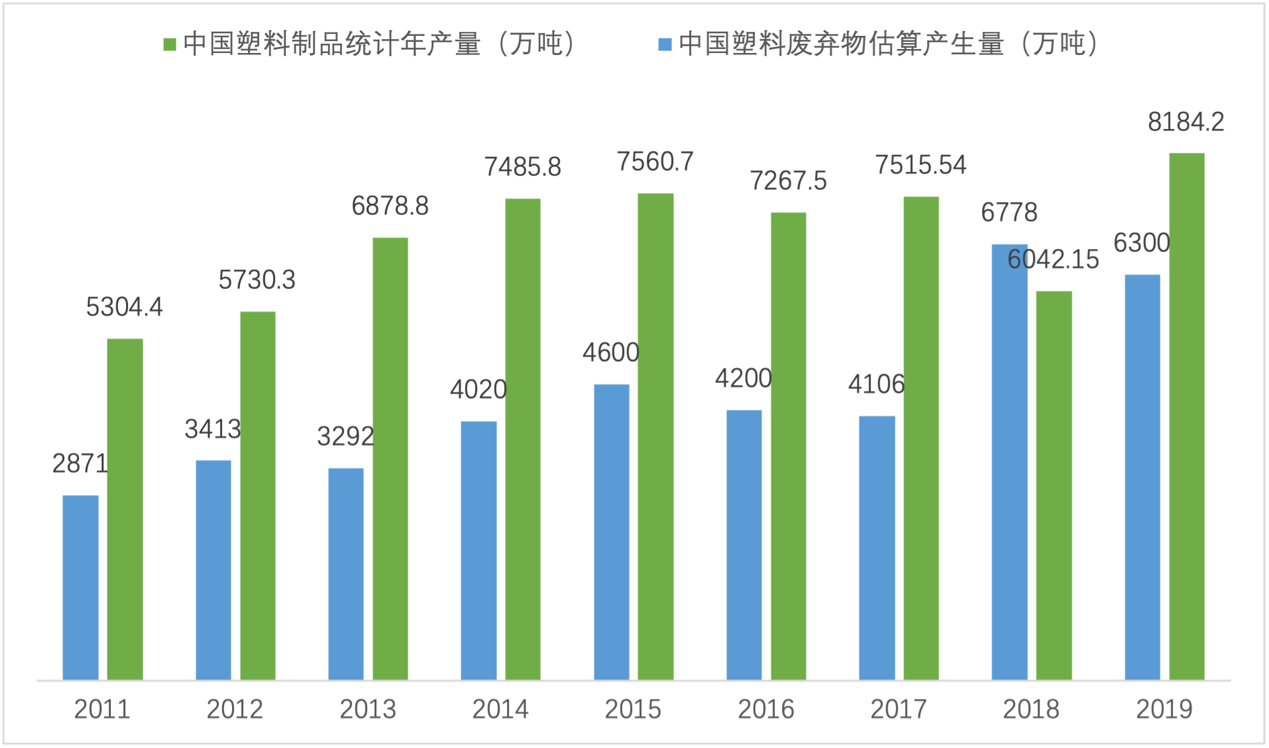

First, China's waste plastic production is still in a period of growth.In recent years, the production of primary plastic products and waste plastic in China has been increasing (see Figure 1). In 2019, per capita plastic consumption in China was 58.45 kg, which is still far behind the 130 kg per capita consumption in the United States. In addition, due to the impact of COVID-19 in recent years, there is still a large room for growth in plastic consumption.

Figure 1 Cumulative annual production of primary plastic products in China Source: Zhongshang Industry Research Database

Figure 2. Production and Waste of plastic products in China Source of data: The author collates according to relevant data

Second, the competent departments and industry associations gradually formulate corresponding standards and norms.Since 2019, China has started to formulate technical standards for recycled plastics. Up to now, eight standards, including polyethylene (PE) materials and polypropylene (PP) materials, have been formulated. As a key association in the industry, China Synthetic Resin Association Plastics Recycling Branch (CPRRA) is also actively organizing the compilation of a series of standards for the Design of Recyclable Plastic Products, providing guidelines for enterprises to improve product design and promote recycling and recycling.

Third, enterprises in the production technology of recycled plastics has been more mature.At present, four domestic enterprises have been evaluated by FDA and obtained food grade recycled plastics production certification. The successful practice of the enterprise has proved that there is no obstacle in the production technology of recycled plastics in China, and the original recycling technology of plastic has been successfully operated by the enterprise for more than ten years.

Fourth, the international environment requires enterprises to increase the proportion of recycled plastics.Under the influence of EU carbon border regulation mechanism, plastic tax and UK plastic packaging tax, the export costs of foreign trade enterprises increase and their economic benefits decrease. In response to the strict environmental standards set by developed countries, Chinese enterprises are required to produce products containing recycled plastics according to the requirements, and there is an increasing demand for high-quality recycled plastics. In addition, Chinese consumers have a high acceptance of plastic recycling, according to the survey, 13.17 percent of consumers will reuse empty plastic bottles on their own. 60.22% of consumers choose to sell waste products for recycling.

C、Internationally, the application of recycled plastics has been expanded from the practical level

From a global perspective, the synergistic effect of recycled plastics in reducing pollution and carbon has been reflected in the practice of many countries around the world. From the perspective of the goals committed by various countries, the international community has begun to promote the application of recycled plastics through mandatory measures such as packaging tax and carbon tariff, and the proportion of recycled plastics is constantly increasing.

(a)The global market for recycled plastics is in short supply

The global market for recycled plastics was estimated at $37.8 billion in 2018, growing to $44.3 billion in 2021 and expected to reach $76.5 billion in 2028. The international market for recycled plastics will continue to expand as the conflict between Russia and Ukraine increases energy costs. According to statistics, the proportion of recycled plastics in the global packaged goods and retail sector has been rising, and almost all internationally renowned consumer goods brands have made a commitment to use recycled plastics.

Table 1 Some enterprises that have published their commitments on recycled plastics use

| No | Brand owner | Total plastic packaging in 2020 (10,000 tons) | Reusable, recyclable, compostable packaging design proportion (%) | High quality recycled plastics in plastic packaging (%) | ||

| 2020 | 2025 Goal | 2020 | 2025 Goal | |||

| 1 | Nestle | 126.7 | 61 | 100 | 4 | 30 |

| 2 | Pepsi | 235 | 77 | 100 | 5 | 25 |

| 3 | Unilever | 69 | 52 | 100 | 11 | 25 |

| 4 | Coca-Cola | 296.1 | 99 | 100 | 11.5 | 25 |

| 5 | Mars | 17.9 | 22 | 100 | 0 | 25 |

| 6 | L 'Oreal | 13.8 | 41.7 | 100 | 15.8 | 50 |

| 7 | Danone | 71.7 | 67 | 100 | 10.3 | 50 |

| 8 | Mondelēz I | 19 | 5 | 100 | 0.3 | 5 |

| 9 | Henkel | 34.8 | 79 | 100 | 12 | 30 |

| 10 | Colgate | 28.8 | 60.8 | 100 | 10 | 25 |

| 11 | Diageo | 4.2 | 66.8 | 100 | 5.4 | 40 |

| 12 | Reckitt Benckiser | 22.5 | 61.8 | 100 | 3.5 | 25 |

| 13 | The sc | 9.4 | 65.5 | 100 | 18.8 | 25 |

| 14 | Kellogg's | 6.5 | 14.1 | 100 | 0.1 | 10 |

| 15 | Exirui | 4 | 18 | 100 | 2 | 25 |

| 16 | Frieslanda Campani | 6.9 | 28.2 | 100 | 1 | 15 |

(b)The proportion of plastic primary grade circulation increased rapidly

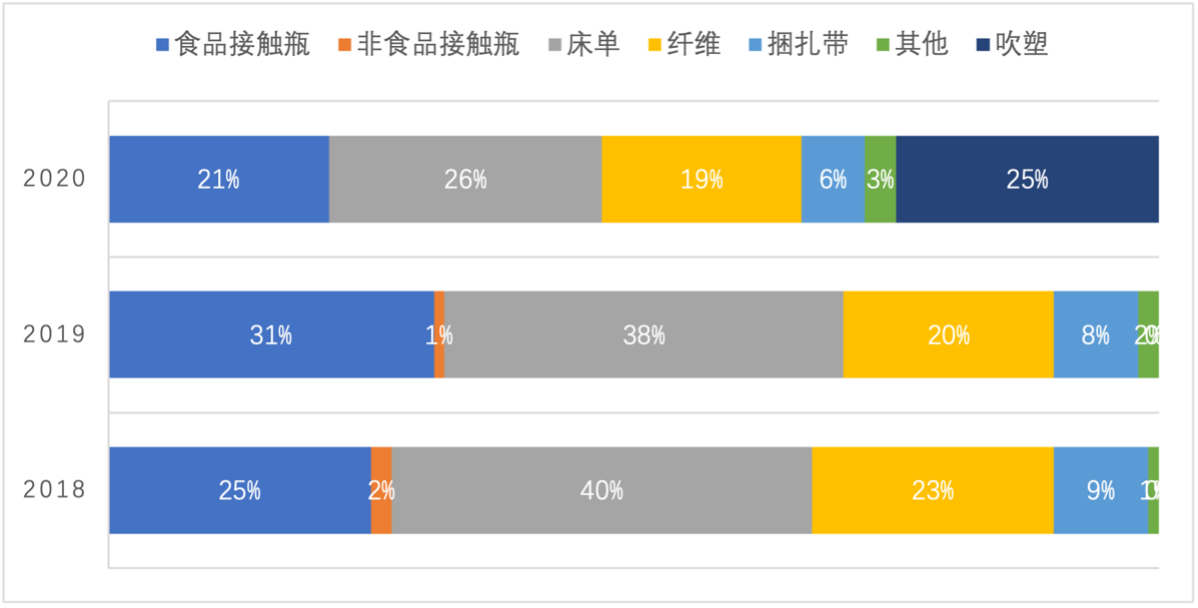

Developed countries have actively explored various methods such as chemical recycling, greatly increasing the proportion of waste plastics recycled into high-quality recycled plastics. On 30 March 2022, the EU issued the EU Strategy for Sustainable and Recycled Textiles, which prohibits the physical recycling of plastic bottles into textile fibers. The aim is to protect the closed-loop recycling system of plastic bottles and promote the primary recycling of plastic. The proportion of primary recycling of plastic has been rapidly increased.

Figure 3 Application of food-grade recycled polyester plastics in EU end markets Source: CPRRA Plastics Recycling Branch

(c)The concept of recycled plastic consumption has gained popular support

Recycled plastic products have become more common in foreign countries. Europe attaches great importance to integrating environmentally friendly packaging into the current consumption methods, such as fast food packaging, prepared food, soft drinks, snacks, etc. The content of recycled plastic in all plastic packaging in the UK has reached 13%. A survey in Germany shows that 95.5% of the people do not buy plastic bags when shopping; 57% of consumers refuse to buy single-use plastic bags; A whopping 72 percent of consumers support a surcharge for using plastic bags.

(d)Regulations and other mandatory measures will be adopted to expand the use of recycled plastics

A growing number of countries are mandating policies that use recycled plastics for packaging (see chart 2). The European Union requires that the proportion of recycled plastics used should increase by four times by 2030 compared with 2015. Australia has specified in its National Plastics Plan 2021 that the content of recycled plastics in plastic packaging should reach 20% by 2025.

Table 2 Some national regulations on the use of recycled plastics

| Country or region | provisions | requirements |

| Britain | It will come into effect on April 1, 2022 "Plastic Packaging Tax" | The plastic package weighs more than 10 tons and contains less recycled plastic A duty of 200 pounds per ton of plastic packaging will be imposed on 30% of goods. |

| Thailand | Plastic Waste Management Plan 2018-2030 | By 2030, the goal will be to eliminate four single-use plastics in order to make Use environmentally friendly, renewable materials |

| Ministry of Public Health Bulletin No. 435 Quality Standards for Plastic Containers of Food Grade | Set quality standards for containers made from recycled plastics of food grade | |

| The United States | Federal Food, Drug, and Cosmetic Act, Compliance Policy Guidelines | Allow recycled plastics to be used in food packaging. |

| S&p Global publishes "Sustainability Indicators | The ESG assessment for the consumer goods industry sets the weight of waste management and environmental pollution at 40%, with a strong emphasis on the recycling proportion of plastic packaging. | |

| Italy | The "plastic tax" is included in the Italian annual Budget law. | Plastic bags will be banned in 2013, cotton swabs made of plastic will be banned in 2019, and a tax of 0.45 euros per kilogram of single-use plastic for packaging will be imposed from 2021. |

| The French | French Circular Economy Law | Single-use plastic bags, plastic paper scraps, cup LIDS and fruit and vegetable packaging will be banned from 2016, and they will be used in households from 2022 All food packaging for daily delivery or on-site consumption must be reusable. |

Green Growth Energy Transition Act Article 173 | Explicitly require listed companies, banks and credit providers, and institutional investors to disclose how the company's investment and risk management policies are How to integrate ESG standards, and how to facilitate energy and ecological transformation. | |

| Basel Convention | In 2019, provisions were added to regulate the disposal of plastic waste in international trade and to require greater transparency in trade | |

(e)Promote the use of recycled plastics through international conventions and carbon tariffs

In March 2022, the Fifth United Nations Environment Conference adopted the Global Agreement to End Plastic Pollution. Many countries, such as France, the United Kingdom, Chile, the Netherlands, South Africa, the United States, Canada, Kenya and India, have also formed national plastic conventions and reached regional agreements, all of which require increasing the recycled plastic content in plastic packaging. At the same time, the Council of the European Union approved the EU Carbon Tariff (CBAM), which is expected to come into force in 2023, including the plastics industry. The global plastic packaging industry may face the pressure of global convention and "green trade barriers" brought by carbon tariffs in the future. As the phased target of recycled plastics content in various countries continues to be defined, it is necessary for China to formulate corresponding policies, regulations and standards as soon as possible to effectively expand the proportion of recycled plastics used.

D、The main problems facing China in expanding the use of recycled plastics

It is found that although the application of recycled plastics in China has a good foundation for development, the proportion of recycled plastics used in the way of recycled plastics is relatively low, and the utilization rate of recycled plastics reaching the original grade quality after treatment is less than 2%. There are still policy bottlenecks to expand the application of recycled plastics.

First, at present, plastic recycling is mainly degraded cycle. From the current situation of recycling of waste plastics in China, it is still mainly linear treatment, rather than multiple recycling. It is difficult for most plastic products to enter the recycling channel again after being degraded and recycled for one time, and the proportion of original grade plastic recycling application that can be recycled for several times is only about 2%.

Second, the food grade plastic primary grade recycling policy has not been clear. Among the recycled plastics, PET, PE and other food-grade plastics are currently mainly used in the production of textile fibers, agricultural film, industrial packaging film, or the manufacture of fertilizer packaging bags, garbage bags, agricultural recycled water pipes, geomaterials, etc., which have not yet realized the original recycling. Although a considerable number of Chinese enterprises have the technical capacity to produce food-grade recycled plastics, they have no choice but to export their products overseas without clear policies.

Third, the lack of perfect plastic recycling system and infrastructure. China has not yet built a systematic recycling system for plastics. In most places, plastic lunch boxes and disposable plastic packaging are not included in the low-value recyclables system in the garbage classification standards, so they can only rely on local spontaneous and scattered scavengers or individual businesses to recycle. Consumers have insufficient understanding of garbage classification and recycling of all plastics, and the participation of consumers in the classification of rigid plastic packaging is not high. Infrastructure construction such as recycling, sorting, transportation and utilization of renewable resources has not been included in the overall urban planning, resulting in increased collection and transportation costs for recycling enterprises.

Fourth, the technical standardization of the whole industrial chain of recycled plastics needs to be improved. The standardization construction of recycled plastics in China needs to be improved. Compared with the unified international technical standard for high-quality recycled plastics (PCR) industry, China lacks unified technical standard and chain of custody for recycled plastics, as well as independent certification system. At the same time, there is a lack of standard links between plastic recycling and front-end plastic production. Taking plastic lunch boxes as an example, there is no unified technical standard for the production of Chinese lunch boxes, and the large design differences lead to a large occupation of packing space, resulting in low clearance efficiency. The mixing of different materials is not conducive to the high value utilization of recycled plastics.

Fifth, the food grade plastic original grade recycling cost is higher. According to the actual survey of the recycled plastic production enterprises with the largest single-line capacity in Asia, the main costs of PET recycling process are as follows: the cost of recycled bottle is 2000-4500 yuan/ton; The cost of bottle pieces is 5000-6000 yuan/ton; The production cost from bottle flake to particle is about 1000 yuan/ton; Particle purification and viscosification process is about 1500 yuan/ton; The cost from bottle sheet to recycled sheet is about 2000 yuan/ton. Combined with the above analysis, the cost of recycled chemical fiber grade bottles is about 5000-6000 yuan/ton; The cost of food-grade recycled particles is about 9000 yuan/ton; The cost of food-grade recycled sheet is also about 9000 yuan/ton. It can be seen that at this stage, compared with the use of raw materials, high-quality plastic primary cycle lack of cost advantage.

E、Policy suggestions for increasing the proportion of recycled plastics

Expanding the application of recycled plastics has become the top priority of pollution reduction and carbon reduction in China's plastic industry, so we should advance the layout and accelerate the expansion of the application scale of recycled plastics.

(a)Through policy guidance and encouragement to increase the proportion of recycled plastics application

With the goal of recycling waste plastics and reducing carbon, policies and regulations should be formulated to strengthen the application of recycled plastics by enterprises, and gradually raise the requirements to expand the application proportion of recycled plastics in enterprises' products. At the same time, enterprises are encouraged to take the initiative to add labels of recycled plastics content in product descriptions, establish relevant information disclosure systems, regularly publish recycled plastics application data, fulfill the obligation to inform the competent authorities and the public, and accept their supervision.

(b)As soon as possible to formulate a list of recycled plastic pollutants replacement and national standards

We will conduct a survey on the level of recycled plastic pollutants in China and systematically compare them with those in the United States and the European Union. Based on the survey results, we will establish an alternative list of recycled plastic pollutants in China. Green standards such as environmental protection evaluation, cleaner production evaluation and recycling of recycled materials (such as rPET original recycling standard) have been formulated for the production equipment of the recycled plastics industry. Standards and requirements have been clearly defined from raw materials, production process, product quality and other links, providing standard basis for enterprises and other implementation units, and increasing the public's trust in recycled products. At the same time, the mutual recognition of domestic management standards and international institutions will be accelerated to promote the export of products.

(c)Use economic means to promote the high quality development of plastic recycling enterprises

According to the characteristics of the recycled plastics industry, strengthen government procurement, tax incentives and other economic support. We will effectively reduce the operation and management costs of enterprises, enhance their price competitiveness, and expand the scale of the renewable resources industry. Through the establishment of special funds, social commendation and other ways to increase support for the research, development and production of recycled plastic products, circulation management, recycling facilities construction and other projects, to provide a strong guarantee for the further development of the industry.

(d)Strengthening the construction of waste plastic recycling system and direction supervision system

A closed-loop recycling and disposal system is established at the front end, and a closed-loop management mode is realized among producers, sellers and buyers according to the principle of "buyer return - seller recovery - producer disposal". We will improve waste classification standards, and incorporate infrastructure such as plastic recycling stations and sorting centers into urban planning. Further develop and optimize the intelligent recovery platform to improve recovery efficiency and reduce operation and maintenance costs. Enterprises that produce and use disposable plastic packaging will be included in the extended producer responsibility system and urged to increase the proportion of plastic recycling. Make full use of big data and Internet of Things technology to gradually build a controllable and traceable supervision system for the flow of plastic products, and monitor the whole process of the circulation of plastic products.

(e)Pilot projects for recycling plastics will be launched in areas and enterprises where conditions are ripe

On the basis of enterprises with mature high-quality recycled plastics production technology and good social credit, and combined with the existing garbage classification system, pilot recycling of recycled plastics of primary grade will be carried out. During the pilot period, the quality of recycled plastic products shall be supervised in real time, the effectiveness of the pilot units and the problems and difficulties encountered shall be summarized, the successful model of the pilot shall be promoted, and the proportion of recycled plastic application shall be gradually expanded.

English

English

中文简体

中文简体